In the relentless battle against thermal challenges that plague both industrial complexes and humble domestic spaces, heat resistant tape emerges as an unsung hero, a silent sentinel guarding against the tyranny of extreme temperatures. This remarkable adhesive innovation, though often overlooked in the grand tapestry of modern materials, performs its duties with unwavering dedication, protecting surfaces and junctions where conventional tapes would surrender to the merciless embrace of heat.

The Alchemy of Thermal Resistance

The magic of these adhesive wonders lies not in some arcane sorcery but in the sophisticated chemistry of their construction. Like ancient alchemists pursuing the philosopher’s stone, material scientists have conjured formulations that defy the natural order of things, creating bonds that remain steadfast even as mercury rises in thermometers.

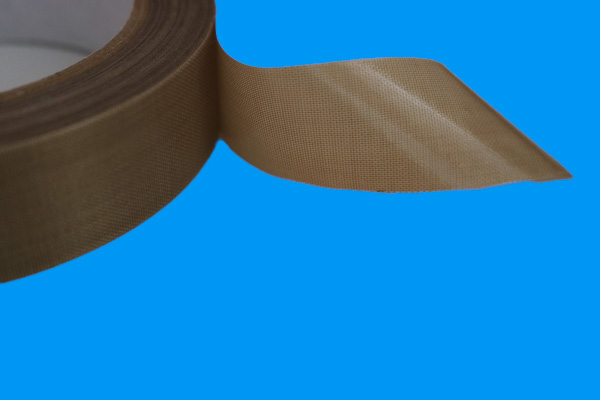

Most heat resistant tapes employ silicone, fibreglass, or polyimide bases, sometimes adorned with sophisticated adhesives that maintain their grip when ordinary glues would melt away like morning dew under a scorching sun. These materials dance together in a complex choreography, each playing its part in the grand performance of thermal protection.

A Tapestry of Applications

The applications of these thermal guardians spread across industries like a sprawling epic, each chapter more fascinating than the last:

Automotive Enchantment:

In the infernal chambers of engines, where metal and fire commune in eternal dialogue, heat resistant tape shields wiring harnesses and hoses from the ravages of combustion

Aerospace Marvels:

Within the steel birds that soar through azure skies, these tapes secure components against the extreme temperature fluctuations of stratospheric journeys

Electronics Protection:

The miniature universes within our devices, where electrons flow like cosmic rivers, rely on these tapes to manage heat and prevent the apocalypse of thermal runaway

Industrial Safeguarding:

In factories where furnaces roar like mythical dragons, these adhesive strips seal, mark, and protect, standing vigilant against temperatures that would reduce lesser materials to cinders

“Singapore heat resistant tape products have revolutionised our manufacturing processes, allowing us to maintain precise thermal control in environments where conventional solutions would fail spectacularly.”

The Chronicles of Selection

Choosing the appropriate variant from this family of thermal warriors requires discernment worthy of an ancient sage. One must contemplate:

1. The maximum temperature the tape must endure a number that varies from the modest 100°C to the astonishing 1000°C for certain ceramic-based champions

2. The duration of exposure whether a fleeting encounter with heat or a prolonged siege of elevated temperatures

3. The surface upon which it shall be applied smooth as a maiden’s cheek or rough as the bark of an ancient banyan

4. The environmental conditions the presence of moisture, chemicals, or other agents that might undermine its valiant efforts

Tales of Application

The ritual of applying heat resistant tape demands attention to detail that would please even the most fastidious of scribes. First, one must prepare the surface, cleansing it of oils and contaminants that might betray the tape’s adhesion. Then, with deliberate movements, the tape must be applied with sufficient pressure to activate the adhesive, avoiding the twin demons of bubbles and wrinkles that might compromise its integrity.

“Singapore heat resistant tape manufacturers recommend applying firm, even pressure and avoiding stretching the tape during application to ensure optimal thermal protection.”

Some varieties require a period of curing, a time of meditation and transformation during which the adhesive bonds with the surface in a sacred union of protection. Others perform their duties immediately, requiring no such courtship before assuming their protective mantle.

The Economy of Protection

Though the initial investment in quality heat resistant tape might appear higher than its ordinary cousins, this expense reveals itself as wisdom when viewed through the lens of longevity and protection. Like a well-crafted epic that endures through generations, premium heat resistant solutions provide value that transcends their modest cost, preventing damages that would demand far greater treasures to repair.

In this cosmic balance of expenditure and benefit, one finds that the judicious application of heat resistant tape offers returns that compound like interest in the bank of industrial reliability and safety.

The Eternal Flame of Innovation

The narrative of heat resistant tape continues to evolve, with researchers pursuing ever more resilient formulations. Like characters in an unfinished novel, these tapes transform with each technological breakthrough, incorporating nanomaterials and advanced polymers that push the boundaries of what was once thought possible. Their evolution mirrors our own technological journey, constantly adapting to more demanding applications and more extreme conditions, a testament to human ingenuity in the face of thermal adversity.

The Final Verse

As our exploration of this remarkable material draws to a close, we stand in appreciation of its quiet contribution to the machinery of modern life. From the humblest household repair to the grandest industrial installation, these tapes perform their duties with a stoicism that borders on nobility, asking nothing in return save for proper selection and application. In a world increasingly defined by technological marvels and complex systems, there remains something profoundly satisfying about the elegant simplicity and effectiveness of heat resistant tape.